“What invisible flaw could bring down a massive jet, and how did it escape detection despite routine inspections?”

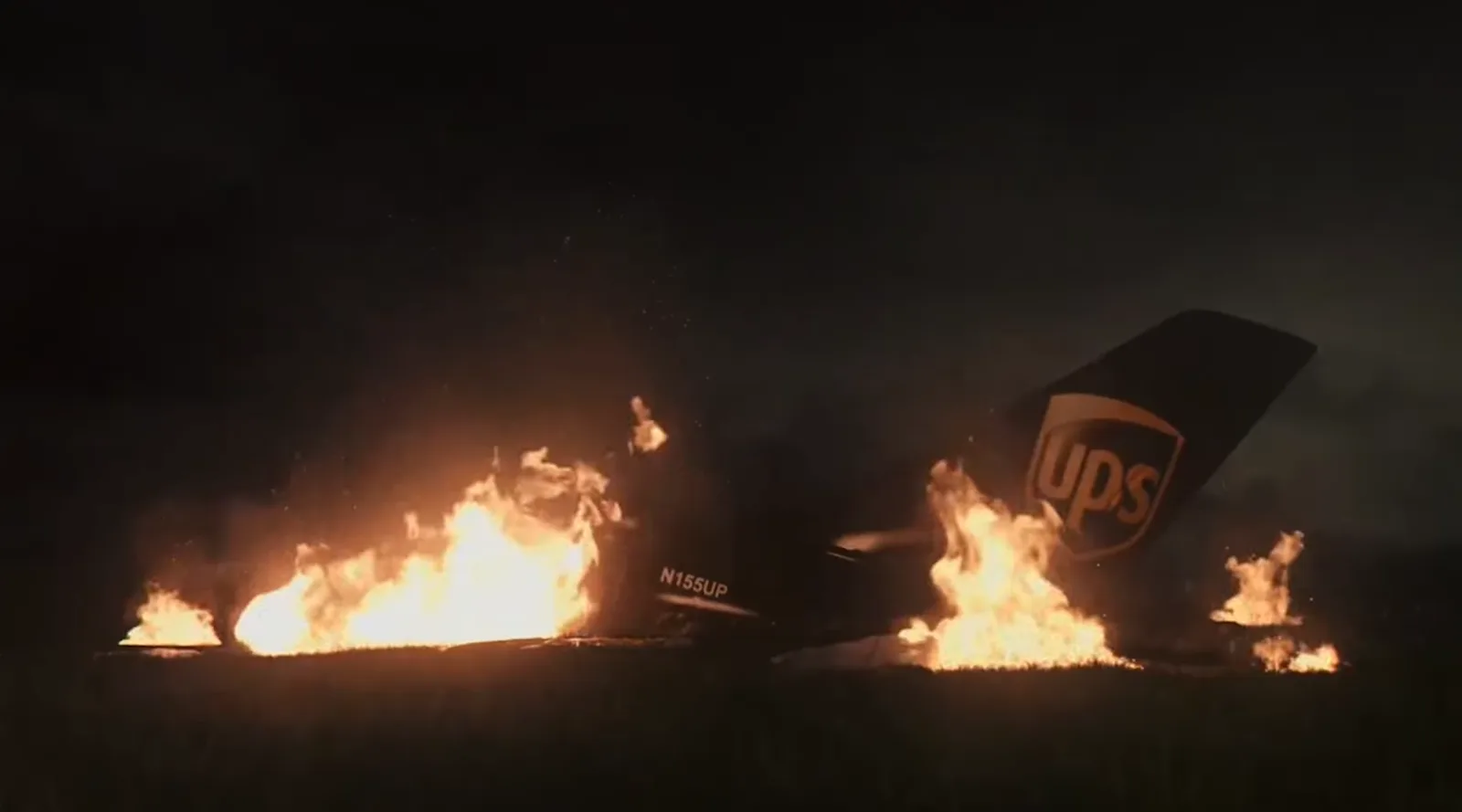

When a UPS cargo plane exploded just seconds after takeoff, it wasn’t just a tragedy—it was a mystery that left experts scratching their heads for years.

A small crack, hidden deep within the metal, transformed a trusted aircraft into a deadly fireball.

How did such a tiny flaw go undetected, and what did it reveal about aviation safety? Stay tuned, because the shocking truth is about to unfold.

The Fateful Day: A Routine Flight Turns Deadly

On the morning of November 4th, 2025, a UPS cargo jet was supposed to take off for a routine flight from Louisville to Dallas.

The weather was calm, the skies clear, and the three experienced pilots were ready for another cargo run.

But, within seconds of takeoff, the unimaginable happened.

Witnesses on the ground saw flames burst from the left wing, followed by a thunderous explosion that engulfed the sky.

The aircraft quickly lost altitude, tilting sharply, and crashed near a metal recycling yard just beyond the airport fence.

CCTV footage showed a violent moment when the left engine ripped away from the wing.

The flames erupted from the engine joint, the critical area that holds the engine to the plane.

It was clear: this wasn’t just a mechanical malfunction—it was something far worse.

The Search for Answers: What Went Wrong?

Rescue crews arrived to a scene of utter chaos.

Twisted metal, flames, and the wreckage of what had been a plane just moments before.

Despite hours of battling the flames, investigators were stumped—there was no obvious explanation for such a catastrophic failure.

What happened to the left engine?

The plane had been carefully maintained and thoroughly inspected before its flight.

So how did a seemingly minor flaw turn into a disaster? What was hidden beneath the surface of the aircraft, undetected for years? The clues would come from the black boxes and further investigation into the aircraft’s maintenance history.

The Key Discovery: A Tiny Crack That Went Unnoticed

The flight data recorder and cockpit voice recorder provided crucial insights.

Seconds after takeoff, the warning alarms went off, signaling a catastrophic failure in the left engine assembly.

The pilots responded quickly, activating fire suppression systems and cutting fuel lines, but the damage was already done.

The left engine was no longer securely attached to the wing, and the jet’s controls were severely compromised.

As investigators combed through the wreckage, they examined the engine pylon—the component that connects the engine to the aircraft.

What they found stunned them: the pylon had fractured in a way that indicated metal fatigue, something that had been growing for years without anyone noticing.

The crack’s discoloration and uneven breaks pointed to previous repairs that had failed to address deeper issues.

The Hidden Danger: The Fatigue That Went Unseen

The fatigue crack had formed years earlier, during a 2019 repair after a minor fatigue crack was found in the pylon.

At that time, the pylon was welded and reinforced with a support plate.

The repair was certified as successful and the aircraft returned to service.

But the reality was more sinister—hidden beneath the surface were microscopic fractures that slowly grew with every flight.

By the time the plane was airborne on that fateful morning, the crack had become a ticking time bomb.

When maximum thrust was applied during takeoff, the welded pylon snapped under pressure, triggering a devastating fire and causing a catastrophic failure of the aircraft’s vital systems.

What had passed every visual inspection for years was finally exposed as the silent threat that had been lurking unseen.

The Broader Problem: Gaps in Aircraft Maintenance

The failure of this aircraft’s pylon raised a troubling question: How many other planes, operating on visual inspections alone, might have hidden structural failures? The lack of rigorous testing, such as ultrasonic scans to detect microfractures, meant that older aircraft could be carrying invisible flaws, waiting to explode into disaster.

Despite repeated warnings from aviation experts, visual inspections have remained the standard for many older planes.

Microscopic cracks can develop deep within the metal, undetectable to the naked eye.

Without the required non-destructive testing methods, aging planes could be flying with critical flaws, putting lives at risk.

The Industry Reckoning: What Needs to Change

The UPS flight 2976 crash was a wake-up call for the aviation industry.

In the aftermath, aviation regulators and airlines grounded all MD11 aircraft to conduct thorough inspections.

It became clear that safety standards for aging planes were not enough.

The call for advanced testing techniques like ultrasonic scans and eddy current inspections became more urgent than ever.

However, regulatory changes are still slow-moving.

The industry has been reluctant to adopt more costly and time-consuming safety protocols, opting instead for “good enough” inspections.

The reality, however, is that these inspections missed hidden flaws that only became apparent when it was too late.

The Human Side: The Final Moments Inside the Cockpit

Inside the cockpit, Captain Richard Whartonberg, First Officer Lee Truit, and Flight Engineer Dana Diamond faced a nightmare.

Despite their years of experience, nothing could have prepared them for the catastrophic failure of the left engine.

The warning alarms went off just moments after takeoff, signaling that the left engine was on fire.

The crew’s responses were swift and professional, but the damage was already too severe.

The plane climbed briefly before losing control.

The pilots fought valiantly to regain stability, but it was impossible.

With the left engine compromised and the aircraft’s flight controls destroyed by the spreading fire, the plane plummeted to the ground, crashing just moments later.

The pilots’ final efforts were recorded in the voice recorder, but their actions could not prevent the inevitable.

The Industry’s Lessons and the Road Ahead

The UPS plane crash is a tragic reminder of how small, unseen flaws in aircraft can lead to disaster.

The incident exposed a fundamental flaw in how we inspect and maintain aging aircraft.

Aviation regulators, in response, have called for more advanced inspection methods and stricter maintenance protocols to ensure that planes are thoroughly checked for hidden cracks.

But it also raised questions about how the industry prioritizes safety.

“Good enough” inspections have often been the norm, but the failure to adopt newer, more effective testing methods has now proven to be a deadly mistake.

The industry must evolve, demanding more rigorous standards and proactive maintenance to prevent further disasters like this.

News

“Screaming Silence: How I Went from Invisible to Unbreakable in the Face of Family Betrayal”

“You’re absolutely right. I’ll give you all the space you need.” It’s a mother’s worst nightmare—the slow erosion of her…

“From Invisible to Unstoppable: How I Reclaimed My Life After 63 Years of Serving Everyone Else”

“I thought I needed their approval, their validation. But the truth is, I only needed myself.” What happens when a…

“When My Son Denied Me His Blood, I Revealed the Secret That Changed Everything: A Journey from Shame to Triumph”

“I thought I needed my son’s blood to save my life. It turned out I’d saved myself years ago, one…

“When My Daughter-in-Law Celebrated My Illness, I Became the Most Powerful Woman in the Room: A Journey of Betrayal, Resilience, and Reclaiming My Life”

“You taught me that dignity isn’t about what people give you, it’s about what you refuse to lose. “ What…

“When My Sister-in-Law’s Christmas Gala Turned into My Liberation: How I Exposed Their Lies and Found My Freedom”

“Merry Christmas, Victoria. ” The moment everything changed was when I decided to stop being invisible. What happens when a…

On My Son’s Wedding Day, I Took Back My Dignity: How I Turned Betrayal into a Legacy

“You were always somebody, sweetheart. You just forgot for a little while.” It was supposed to be the happiest day…

End of content

No more pages to load